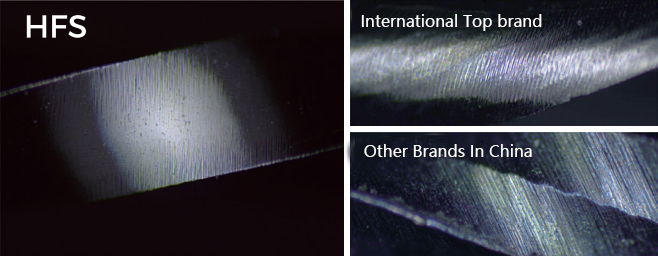

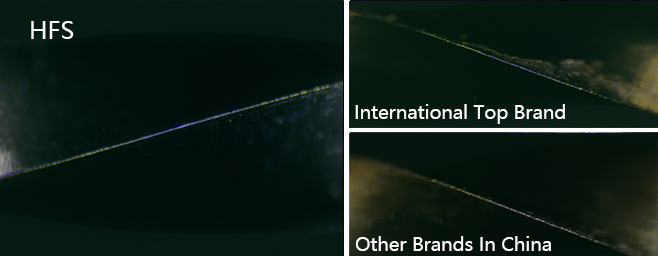

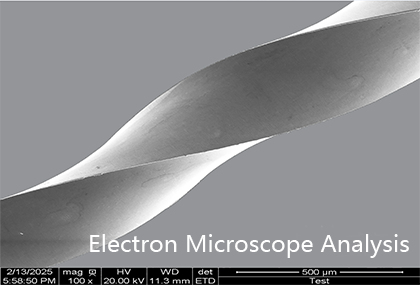

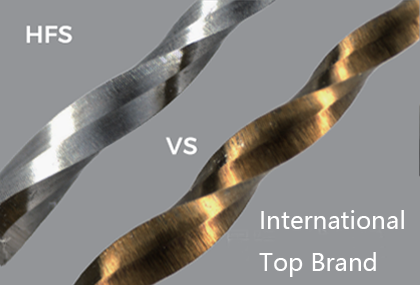

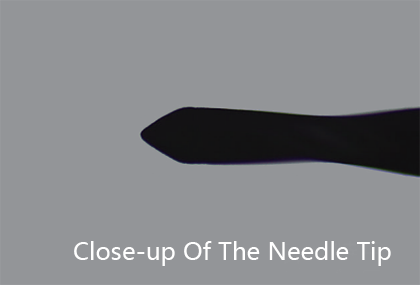

Hephaes VS Other Brands

| Brand | Blade edge (width)μm | Dimension Consistency (accuracy)μm | Roughness (RA)μm |

|---|---|---|---|

| Chinese Brand A | 15.2 | 15 | 0.45 |

| Chinese Brand B | 5.3 | 12 | 0.52 |

| International Top Brand A | 2.5 | 6 | 0.27 |

| International Top Brand B | 2.1 | 5 | 0.29 |

| HFS Medium-low Quality | 2.5 | 7 | 0.13 |

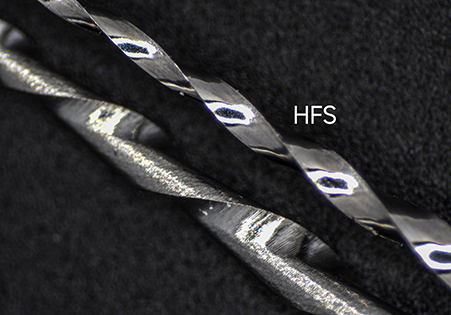

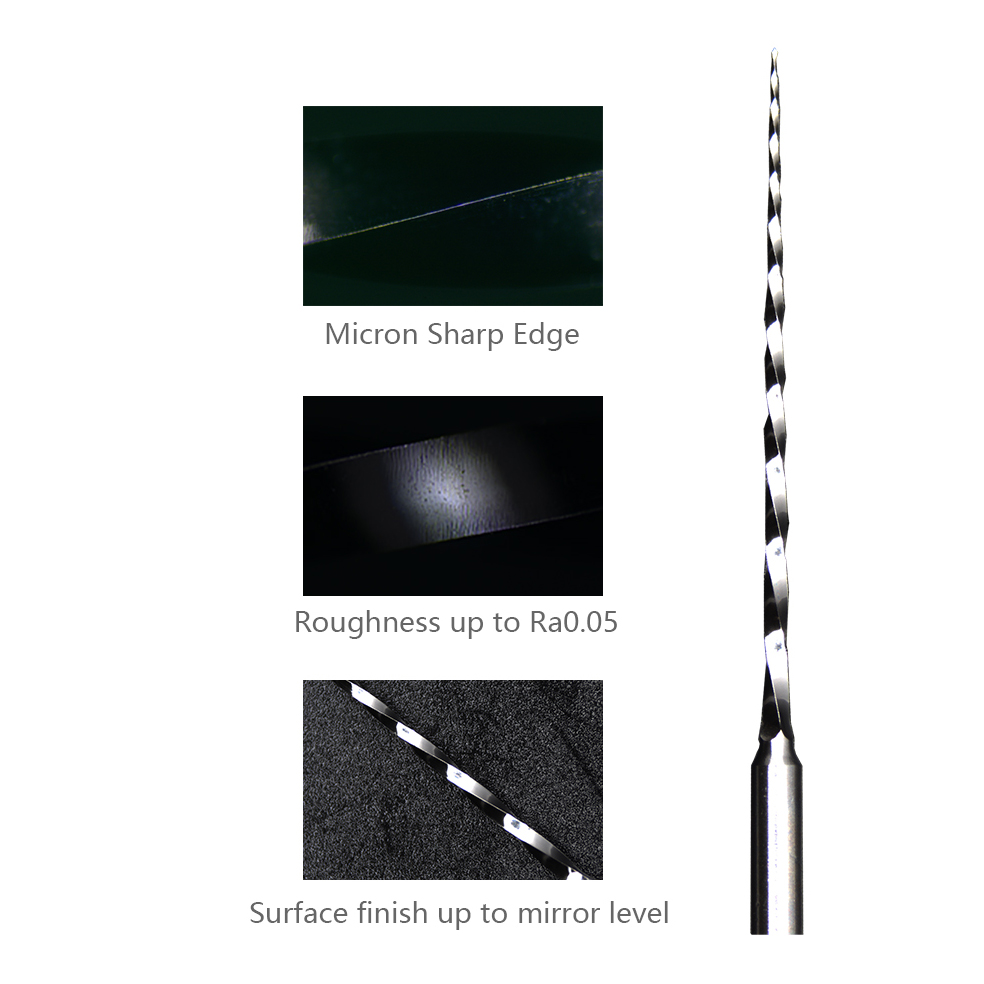

| HFS First-Class | 1.4 | 5 | 0.09 -> After Polishing 0.05 |